Explosion-proof vacuum cleaners are not simply more powerful variations than their more conventional counterparts. Instead, these are high-quality industrial instruments with built-in safety features for removing flammable dust. They are designed to remove materials and liquids that are flammable and possibly explosive from surfaces without setting off an explosion or a fire. Read More…

As a leader in the vacuum cleaner manufacturing industry, Multi-Vac offers vacuums for a variety of applications. Products include central industrial vacuums, portable vacuum cleaners and more.

Delfin Industrial Vacuums is an innovative leader in the vacuum cleaners industry. We focus on continually improving our products and our services, so you are only ever getting the best from us. Our team is dedicated to finding the right industrial vacuum system for your company’s specific needs. Delfin is an ISO 9001 certified company. We offer our customers unrivaled customer service and...

We aim to achieve measurable cost savings for you while producing a cleaner and safer work environment in your workplace. We meet your needs for cleaning or maintaining, recycling, non-destructively excavating, or improving air quality.

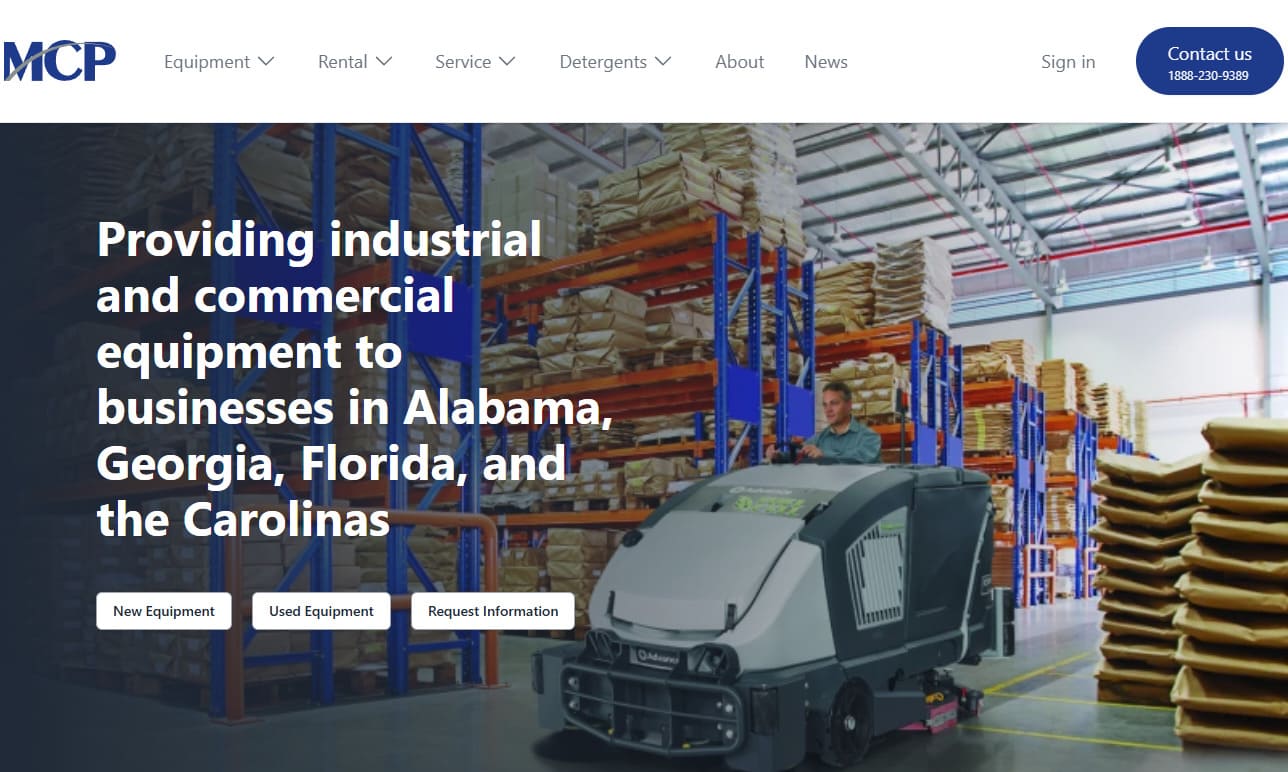

At Mark C. Pope Associates, we take pride in offering advanced vacuum cleaning solutions tailored to meet the rigorous demands of industrial and commercial environments. With decades of experience in the field, we have built a reputation for delivering high-performance vacuum systems that stand up to heavy-duty use while ensuring efficiency, safety, and cleanliness in every application.

More Explosion Proof Vacuum Manufacturers

Features of Explosion-Proof Vacuum Cleaners

A standard explosion-proof vacuum cleaner should have a chemically neutral housing and be able to disperse static charges. Additionally, it features adequate electrical insulation. These are its primary characteristics:

Heavy-duty housing: The equipment can contain any explosion within, thanks to a strong stainless steel outer shell that does not crack or dent. The housing should be built from an anti-sparking substance that reduces the possibility of an electrical discharge-related explosion. A good material for making an explosion-proof vacuum cleaner housing is reinforced fiberglass.

An explosion-proof motor should be able to withstand any internal pressure buildup without exploding, and it should also be able to contain any external pressure. The minimum ignition temperature (MIT) of the combustible materials in the environment around the apparatus should not be exceeded by any gasses or vapor leaving the component through flame routes.

Motors, switches, and air supply lines are examples of grounded parts and accessories. One can guarantee that static electricity is constantly being removed by grounding them, avoiding a dangerous accumulation that can result in an electrostatic discharge.

The immersion separator is a component found in some models of explosion-proof vacuums. Its purpose is to reduce the possibility of combustible dust igniting inside the equipment above. A non-reactive, secure fluid bath gathers and neutralizes flammable metal particles, including magnesium and aluminum.

Explosion Proof Vacuums’ Working Principle

These vacuums lack a motor or other moving parts that could generate sparks or static electricity and instead rely on compressed air to create a vacuum.

Most people think these are a bigger version of a standard shop vac, but they generate suction differently. Explosion-proof vacuums have compressed air forced into them, creating a vacuum effect, instead of a motor spinning a blower fan to create suction.

These industrial vacuums exploit the Venturi effect where a restriction in the air route causes the air to accelerate up and slow down again. It produces low air pressure when it moves through the restriction, which leads to a vacuum. The Venturi effect uses no moving parts or hazardous electrical wires to produce substantially stronger suction than anything an electric vacuum can generate.

In explosion-proof vacuums, compressed air is driven via a compressing nozzle (see diagram below) (B) after being blown into a chamber (A). The air is greatly accelerated when driven through this nozzle; the air velocity is significantly reduced after entering the mixing chamber (C). The vacuum hose's suction is produced using the negative air pressure produced by this air velocity reduction (D) reduction. After being compressed, this mixture of air and dirt from a vacuum is passed through a filter (E).

The vacuums' actual construction and functionality differ the most. In contrast to regular vacuums, which use a motor to create suction, explosion-proof vacuums employ compressed air rather than a motor or other moving elements. This source of suction keeps any explosion from being started by a spark from the motor, heat from the motor, or friction from moving parts.

Additionally, since the vacuum doesn't directly use electricity, there aren't any electrical cables or sparks to worry about potentially producing potentially dangerous situations. Plugs, switches, and arcing motors can generate spark risks in regular electric vacuum cleaners. Sparks and heat can also be produced if a wire is damaged, igniting the dust.

Dust moving through hoses produces static electricity, which can accumulate to the point where it's strong enough to spark a combustible dust cloud. So all of the components of an explosion-proof vacuum are joined together and grounded after that to safely discharge any built-up static, avoiding any spark or explosion threats.

Explosion-resistant vacuums are put on metal drums that collect the dust to keep the dust confined and safe from potential explosion threats. When the drums are full, they are sealed off and discarded. Metal drums are a recognized means of containment for combustible dust, treated as a hazardous material when collected. Regular vacuums often use bags or plastic containers, which must then be dumped into another location for disposal, posing a risk of explosive dust in the new location.

Choosing the Proper Explosion Proof Vacuum Supplier

To make sure you have the most productive outcome when purchasing an explosion-proof vacuum from an explosion-proof vacuum supplier, it is important to compare at least 4 companies using our list of explosion-proof vacuum suppliers. Each explosion-proof vacuum supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each explosion-proof vacuum company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple explosion-proof vacuum companies with the same message.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services