An industrial vacuum cleaner is a powerful piece of cleaning equipment to eliminate dirt, construction waste, industrial trash, and other debris that accumulates after a manufacturing or building operation. Industrial vacuum cleaners are a piece of cleaning equipment that is ecologically friendly since they properly remove and discard pollutants and dangerous material. Industrial vacuum cleaners are used to clean industrial messes, but they may also be used as an environmental instrument to filter and purify the air in factories. Read More…

As a leader in the vacuum cleaner manufacturing industry, Multi-Vac offers vacuums for a variety of applications. Products include central industrial vacuums, portable vacuum cleaners and more.

Delfin Industrial Vacuums is an innovative leader in the vacuum cleaners industry. We focus on continually improving our products and our services, so you are only ever getting the best from us. Our team is dedicated to finding the right industrial vacuum system for your company’s specific needs. Delfin is an ISO 9001 certified company. We offer our customers unrivaled customer service and...

We aim to achieve measurable cost savings for you while producing a cleaner and safer work environment in your workplace. We meet your needs for cleaning or maintaining, recycling, non-destructively excavating, or improving air quality.

At Mark C. Pope Associates, we take pride in offering advanced vacuum cleaning solutions tailored to meet the rigorous demands of industrial and commercial environments. With decades of experience in the field, we have built a reputation for delivering high-performance vacuum systems that stand up to heavy-duty use while ensuring efficiency, safety, and cleanliness in every application.

More Industrial Vacuum Cleaner Manufacturers

Industrial vacuum cleaners are used in dust extraction systems to collect, filter, and purify the air of high particulate concentrations in work settings to create a safe and hygienic working environment.

How Industrial Vacuum Cleaners Work

Industrial vacuum cleaners create negative pressure by using alternating current (AC) power to drive a high-pressure fan. Air and particles are drawn in by the vacuum formed, then sent through a series of filters before being deposited in a bag or collection area.

The idea of negative air pressure—where the pressure outside the collection pipe is higher than the pressure inside—is the foundation for how industrial vacuum cleaners work. The negative pressure draws the air and particles in from the outside.

Types of Industrial Vacuum Cleaners

The different types of industrial vacuum cleaners include:

Central Vacuum Systems

A structure or building is the basis for the design, engineering, and construction of central vacuum systems. They work similarly to a heating or cooling system and are fueled by the building's electricity. A network of tubes that can be installed into the walls or affixed to the ceiling connects them to the central unit. The tube system transports the gathered waste to a sizable enclosure that is furnished with filters, bags, and storage apparatus. Central systems aim to offer an effective way to remove and clean up debris. Unique and created to meet the needs of the building or structure where they are put, central vacuum systems are specific to each installation.

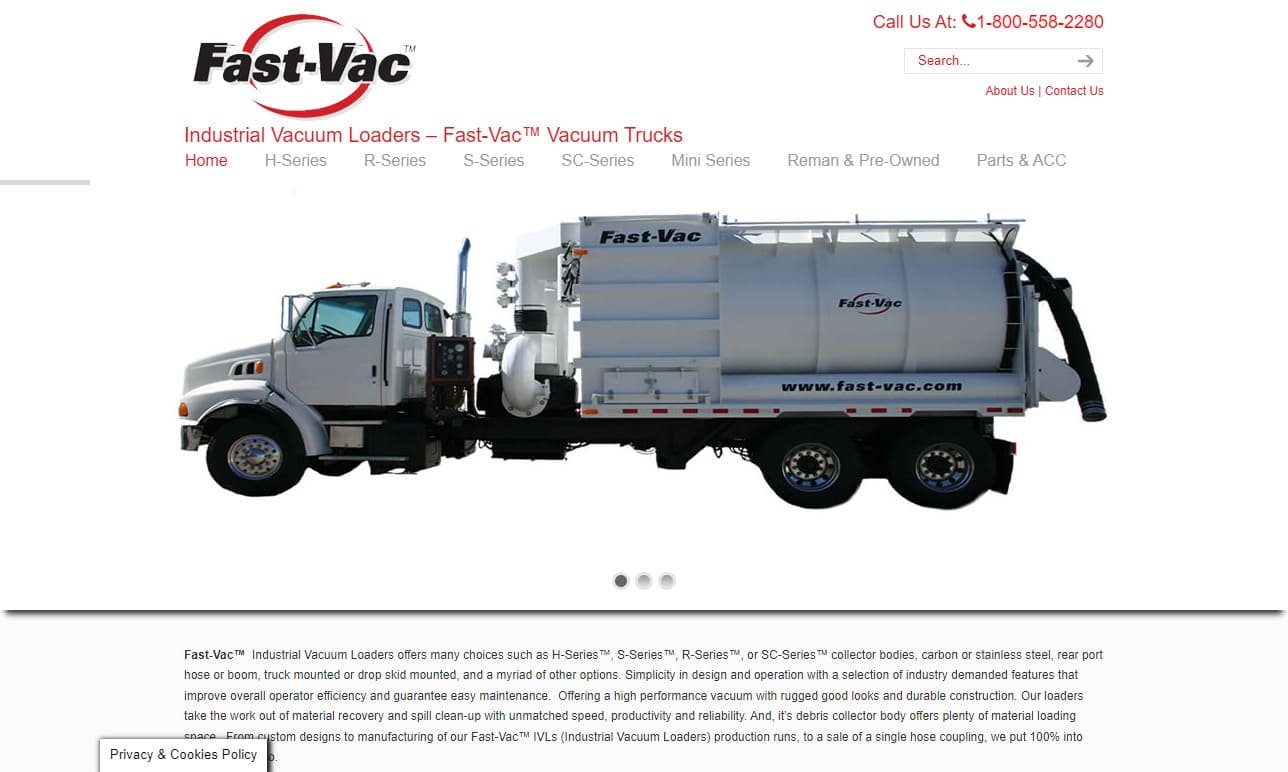

Truck Mounted Vacuum Cleaner

Sludge, slurry, industrial waste, liquids, sewage, and other hazards must be removed from disaster areas and other locations. Truck-mounted industrial vacuum cleaners can move to those places. They operate on the same principles as a standard industrial vacuum cleaner, with a tank for collection and a pump to create negative pressure, although being much larger. The truck's tank is used to collect the waste, which is then moved to a disposal site.

Explosion Proof Vacuum Cleaner

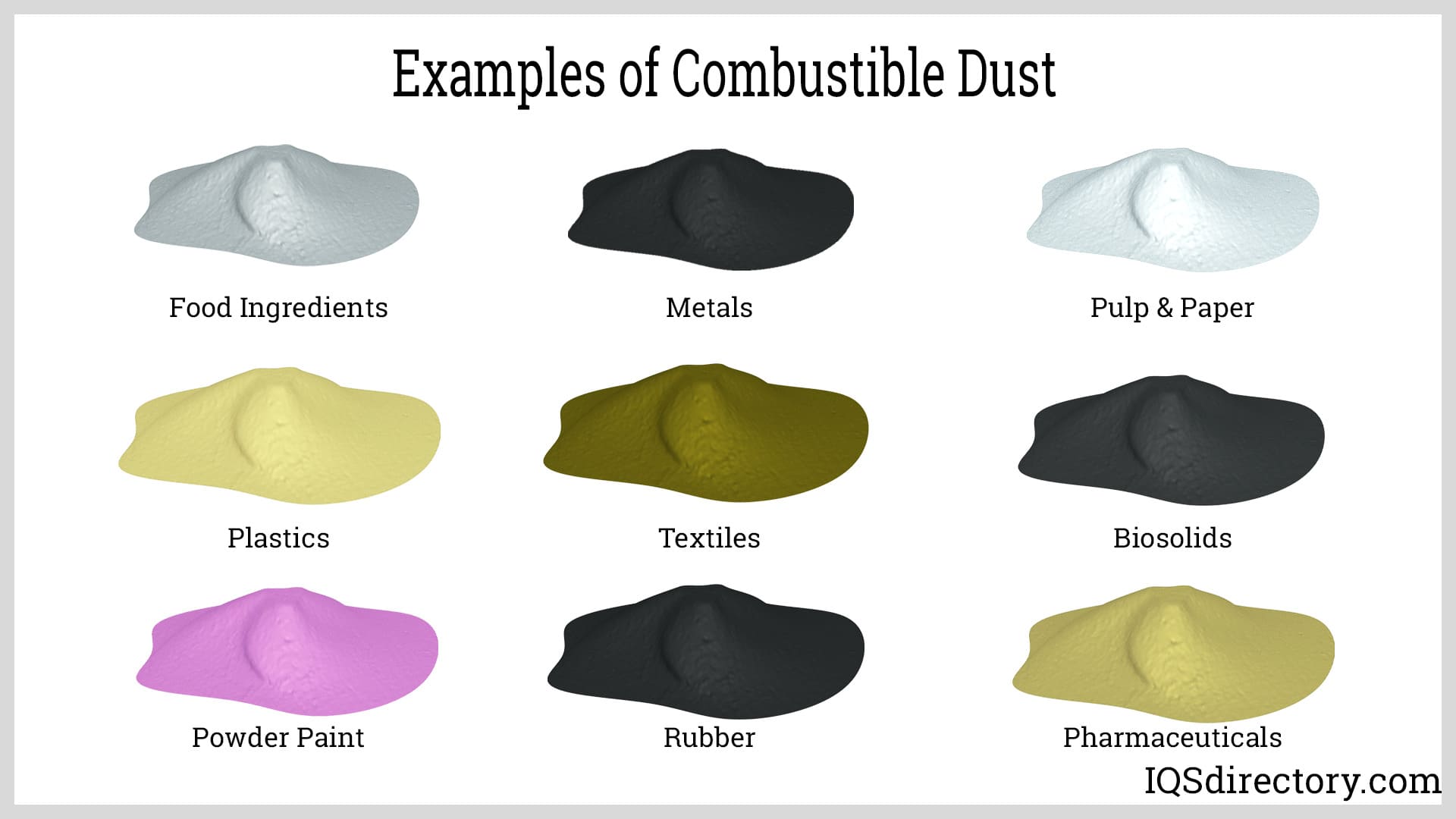

Industrial vacuum cleaners that are explosion-proof are made to remove combustible materials, hazardous solids, and flammable liquids that could catch fire from friction or a spark. They are made of non-flammable materials like metals and fibers to reduce the risk of sparking from friction or static energy buildup. Static dissipation, electrical insulation, and chemical neutrality are all criteria for buildingexplosion-proof industrial vacuum cleaners. The housing, inlets, casters, and nozzles are made of materials that the producers carefully choose to meet these specifications.

Applications of Industrial Vacuum Cleaners

- Due to the considerable amount of powders and paints used during aircraft assembly, the aviation industry is subject to the same regulations as the automobile industry. Clean rooms, which necessitate HEPA filters and high-performance industrial vacuum cleaners, are standard practices in the manufacture of aircraft. An aircraft is carefully cleaned with industrial backpack vacuum cleaners before delivery.

- The key component in baking is flour, which is extremely fine and has a propensity to spread readily during processing. Specially constructed industrial vacuum cleaners are used to collect flour and are not intended to clog up while cleaning. Manufacturers create vacuums with multi-stage filters and filter shakers, which clean the filters and keep them clear, to solve the clogging issue.

- Facilities must be exceedingly clean and free of contaminants per industry standards and regulations. Industrial vacuum cleaners with HEPA filters are used to safeguard the safety of patients and healthcare professionals by eliminating dangerous debris and bacteria. Common vacuum cleaners can be used, but these increase the risk of transmitting airborne infectious materials that industrial vacuum cleaners can otherwise quickly capture and render harmless.

Choosing the Right Industrial Vacuum Cleaner Manufacturer

To make sure you have the most positive outcome when purchasing industrial vacuum cleaners from an industrial vacuum cleaner manufacturer, it is important to compare at least 4 to 5 manufacturers using our industrial vacuum cleaner directory. Each industrial vacuum cleaner manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each industrial vacuum cleaner company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple industrial vacuum cleaner manufacturers with the same quote.

Air Compressors

Air Compressors  Air Filters

Air Filters Air Pollution Control

Air Pollution Control Blowers

Blowers Dust Collectors

Dust Collectors Industrial Vacuum Cleaning Equipment

Industrial Vacuum Cleaning Equipment Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services